Furch Guitars Commits to Clean Power

“The creative path of every musician is marked by a quest for a distinctive style, a style that reflects the player’s musical identity. All musicians strive to be unique, extraordinary, and original and demand the same qualities from the musical instruments they play.” -Furch Guitars

The idea for Furch Guitars began in the 1970s when Frantisek Furch, a Czech metalworker, and musician found himself faced with the unavailability of high-quality musical instruments in the then socialist Czechoslovakia. With little hope of the importation of suitable instruments, Furch decided to put his metalworking skills to use and constructed a banjo from an old drum. Having success in the process, Furch then manufactured a roundback style acoustic guitar from the spruce top plate of an old piano. Friends and fellow musicians loved the new guitar and commissioned Furch to create instruments for them as well.

Despite the ban on private enterprise from the communist regime at the time, Furch’s passion drove him to defy this order, and in 1981, he set up a one-man, garage-based operation to continue producing his beloved instruments. When communism collapsed in 1989, Furch was able to expand his operations, and by 1990 the business moved from the garage to a factory workshop. Furch was then able to hire his first employees.

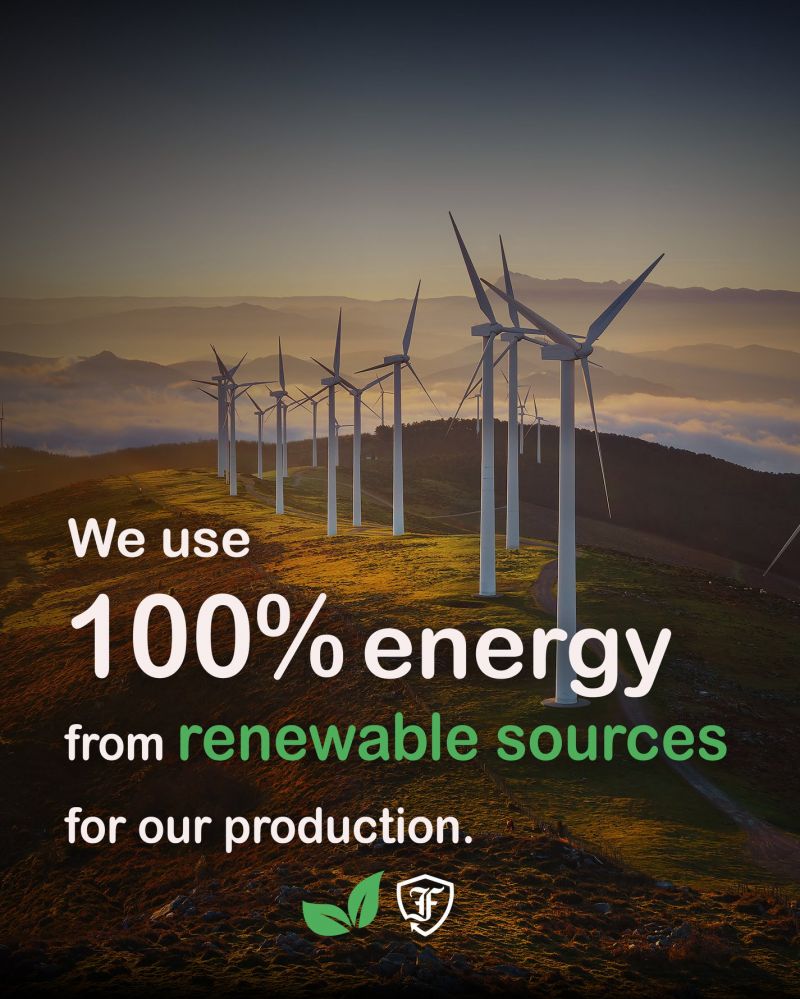

Since its humble beginnings, Furch Guitars has continued to adapt and evolve with the ever-changing demands of the market and its customers. Step by step, Furch Guitars has since become one of the world's leading manufacturers of premium-quality guitars, producing roughly 8,000 instruments per year. Now run by Peter Furch, the company is determined to be on the cutting edge of sustainability and now sources 100% of its electricity from “clean power” or electric power that is produced by methods that use renewable energy resources and do not cause pollution such as solar, biogas, water, wind, and biomass. By switching to renewable resources, Furch states that they “have managed to reduce our overall carbon footprint by up to 83% while maintaining the same level of energy consumption.” We sat down with Furch to discuss this new initiative.

What inspired the decision to source electricity from clean power?

I have been looking into sustainability for our company for quite a few years already; to understand where energy and materials come from, how they happen to exist, and what environmental impact it all has simply interested me. I believe that every growing company will arrive at that way of thinking sooner or later. If you find out what impact you are having, then you naturally look for ways to reduce it.

Is using sustainable resources like this typical in the Czech Republic?

There are individual households that have solar panels and people have a rising interest in building passive houses. This is the evidence that, despite economic disadvantage over a standard way of building a house or obtaining your energy, many people are willing to dedicate a part of their income just to make the environment better. However, for large-scale clean energy production, it is important to motivate large energy suppliers to build sustainable and reliable sources.

How challenging is it to move to 100% sustainable power? Is this something you would recommend to other manufacturers?

For me, in the beginning, the most difficult part was to make sense of the vast amount of information and approaches regarding sustainability in general. Not all approaches out there seem to work in the long term. In my opinion, our way is the most promising and with more companies or consumers on board, it will naturally push the production of sustainable energy up. So, my message for all manufacturers is: Go and ask your energy supplier to deliver certified, sustainable energy and pay a bit extra for it. If they can't deliver, then find someone who can. It will not ruin any one of us individually, but together, we can make a difference.

Does Furch have any more sustainability initiatives in the works for the future?

We are producing acoustic guitars. Particularly the wood of the soundboard is an irreplaceable material in terms of how it behaves acoustically. We will never be able to replace wood in our production, therefore, we want to secure the growth of trees and the goal is to offset our whole production-consumption. With our activities in planting new trees in tropical areas, we are right now at about a 60% offset of our yearly consumption. We will keep improving this number.

What would be your biggest piece of advice for other companies looking to switch to renewable energy sources?

Start with a lifecycle analysis of your products, the energy, and materials you use, and then use common sense to find the right way for your own company. Go after easy solutions with a big impact first and keep going from there.

For more information on Furch Guitars and their green initiatives such as their use of renewable energy visit, https://furchguitars.com/us/.